Trusted Tractor Cardan Joint Factory

"JIUREN AUTO PARTNER" Company Overview

Yuhuan Jiuren Machinery Co., Ltd was founded in 2008 and is a professional manufacturer of steering shafts, drive shafts, and axle shafts. Specialized solutions for cars, trucks, agricultural machinery, and UTVs.

We provide OEM, ODM, and custom services; our products are mainly exported to the USA, Canada, Mexico, Brazil, Argentina, Peru, Australia, New Zealand, Germany, France, the UK, Italy, Netherlands, Poland, Russia, Ukraine, Spain, Hungary, Turkey, Saudi Arabia, Malaysia, Thailand, etc.

In the automotive field, our producta are mainly for Toyota, Honda, Nissan, Mitsubishi, Lexus, Suzuki, Isuzu, Mazda, Daihatsu, Subaru, Infiniti, Mercedes-Benz, BMW, Audi, Volkswagen, Volvo, Porsche, Jeep, Ford, Lincoln, Dodge, Chevrolet, Buick, Cadillac, Chrysler, Hummer, GM, Kia, Hyundai, Land Rover, Jaguar, Renault, Fiat, Peugeot, Opel, Lada, UAZ.

In the truck field, our products are mainly for Mercedes-Benz, Scania, Volvo, Iveco, DAF, Volkswagen, Ford, dump trucks, Basculantes, etc.

In the agricultural machinery field, our products are mainly for John Deere, Case IH, Kubota, New Holland, etc. In the UTV field, our products are mainly for Polaris and Can-Am. Etc.

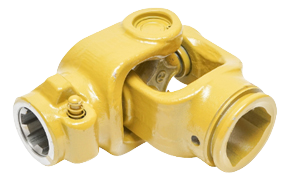

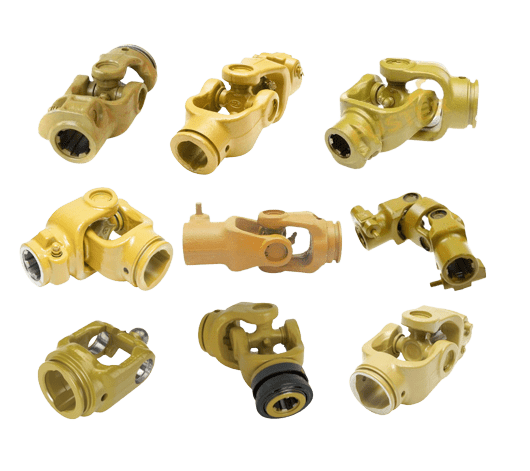

Featured PTO Steering Joint in The Market

How to See The Cardan Joint Quality?

1. Check the appearance

Check the surface treatment for defects, bumps, or rust, then check the finish of the machined surface.

2. Check the burrs

Check the screw holes and keyways for uncleaned burrs, and this detail is something many small factories will overlook.

3. Check the universal joint

Check whether the universal joint oil seal has ruptured; the universal joint is one of the essential parts of the steering joint; if the oil seal ruptures, it will lead to the overflow of lubricating grease inside the bearing cup and the dirt and dust outside into the universal joint, which will lead to the life of the universal joint is significantly shortened.

4. Turning universal joint

Check whether the rotation is smooth; if there is a jam, the steering joint will have a strange sound in the process of use; feel whether there is a gap in the universal joint during the rotation Universal joint if there is a gap, the steering wheel will have a gap after the product is installed, which will affect the precision of the steering wheel rotation, resulting in increased driving danger.

5. Check the length

Measure the correct length of the product.

6. Check the dimensions

Measure the mounting position dimensions, including the diameter of the inner and outer spline, the number of teeth, the spline parameters, and the angle of the mounting position at both ends are correct.

7. Check the thread

Check if the thread specification is correct.

8. Check the spline

Use a thorough gauge to check if the spline parameters are correct.

9. Check other accessories

Check whether other accessories are complete, such as screws, nuts, gaskets, and other accessories.

Production Process of The Cardan Joint

Here is the production process of cardan joints to let you know how they are made.

- 1 . Make a drawing.

Draw the drawing according to the OE sample.

- 2. Make the mold.

Make the mold of the yokes.

- 3. Produce roughs.

Forging or casting the roughs.

- 4. Make the machining.

Machining of these steel parts, turning, drilling and milling.

- 5. Make the spline.

Machining splines.

- 6. Assemble.

Assemble all parts; we buy u joint from “Wanxiang,” the No. 1 brand in the world.

- 7. Make the surface treatment.

Different surface treatments for products according to other products and customer requirements. Painting, electrophoresis, phosphating, galvanizing, zinc-nickel alloy, natural color, etc.

- 8. Laser mark.

Laser mark your logo on the steering joint and coupling surface.

- 9. Packaging.

Bagging and packing them.

Inspection Process of Cardan Joint

- 1. Roughs inspection.

Every rough will be inspected before machining to avoid any defective and missing roughs in the following process.

- 2. Machined parts inspection.

Each machined part will be fully inspected, first by the supervisor of the first inspection, then by the production line workers each full inspection; the inspector will also regularly perform random checks; once found that there is a dimensional failure of the product, it must be immediately dealt with.

- 3. After surface treatment inspection.

Every part that has been surface treated must be thoroughly inspected, and any defective ones cannot flow into the following process.

- 4. Assembled parts inspection.

The workers will self-inspect each product during the assembly process, and the inspectors will also conduct random inspections at regular intervals. Mainly check whether there is clearance in the universal joint and whether there is clearance in the spline shaft and shaft tube fit.

- 5. Finished product inspection.

All finished products will be inspected individually, including checking the appearance and measuring the size, angle, and clearance.

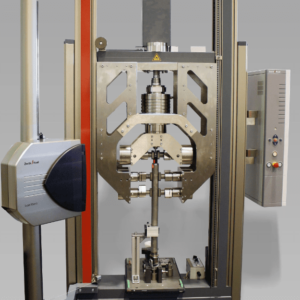

- 6. Performance Testing.

A few randomly selected finished products to do performance testing. Mainly do static torsion test; the test results must reach 300NM or more. Next, do the gap fit test; the test result needs the gap to be less than 0.03mm. Finally, do the fatigue test 1 million times; the test result requires the product to be intact.

- 7. Package inspection.

Packaging is also a full inspection of each product, mainly to see whether the laser typing on the product, bags, boxes, labels, and markings meet customer requirements.

Cardan Joint Package

We offer two packaging models. The first is your branded packaging, and the second is neutral packaging. Whatever your packaging requirements, please let us know, and we’ll take care of it for you!

Brand Packing

- 1. Laser marking your logo on product.

- 2. Put the product in your branded colorful bag.

- 3. Put the bag into your branded colorful box.

- 4. Stick your brand label onto your box.

- 5. Put the boxes into your branded colorful carton.

- 6. Stick your shipping mark onto cartons.

- 7. Make the cartons to pallet or wooden box.

Neutral Packing

- 1. Put the product into white bag.

- 2. Put the bag into neutral brown box.

- 3. Stick neutral label onto box.

- 4. Put the boxes into neutral brown carton.

- 5. Stick your shipping mark onto cartons.

- 6. Make the cartons to pallet or wooden box.

Cardan components listing...

Yokes:Flange Yokes/slip yokes/end yokes/companion flange /weld yokes

Shafts:Spline shafts/ axle shafts/spline stub

| MT-372522 |

| MB-293352 |

| MB-293010 |

| MB-154486 |

| MB-005229 |

| MB-000252 |

| MB-000238 |

| MB-000110S |

| MB-000069 |

| MB-000059 |

| MB-000049-PS100 |

| MB000049 |

| ME629121 |

| MB 154291 |

| MB 000771 |

| F235-14TEETH |

| F235-13TEETH |

| F235-10TEETH |

| F235-0TEETH |

| 8-94460-860 |

| 8-94171-858 |

| 50002-DA2722 5-37211001-0 |

| 41204-37020 |

| 41204-36060 |

| 41204-20030 |

| 41204-87308 |

| 37315-87601 |

| 37315-36020 |

| 37315-20020 |

| 37315-87310 |

| 45104-87303 |

| 37304-36030 |

| 37302-87606 |

| 37302-87506 |

| 37302-87311 |

| 37302-87308/37302-87307 |

| 37302-36020 |

| 37302-36010 |

| 37302-35021 |

| 37302-35010 |

| 37302-20040 |

| 37301-60010 (36010) |

| 37111-01G00 |

| 33324-87311 |

| 33324-87312/ 33324-87603 |

| 33324-87355 |

| 27140-83000 |

| 27131-83001 |

| 353132540 |

| 37111-14600 |

| 27180-83000 |

| 37302-60050 |

| 37302-35030 |

| 37302-35050 |

| 37315-87308 |

| 5920 |

| Ford C-4 , AOD, Ford T5, T-10 Transmission Yoke 1310 series 6.5″ x 28 spline |

| 1480 series slip yoke |

| 1480 series weld yoke |

| 1480 series flange yoke |

| 1480 series spline shaft |

| 1480 series universal joint |

| 1480 series weld part |

| 1480 series weld part |

| GF-601 | 26-118 |

| GF-602 | 2-28-1697 |

| GF-603 | 3-28-537 |

| GF-604 | 4-28-307 |

| GF-605 | 5-28-327 |

| GF-606 | 26-135 |

| GF-607 | 26-163 |

| GF-608 | 26-215C 26-246 |

| GF-609 | 4-28-637 |

| GF-610 | 3205 |

| GF-611 | 82-1564 |

| GF-612 | 2-28-437 |

| GF-613 | 2-28-357 |

| GF-614 | 90-28-27 |

| GF-615 | 26-227 |

| GF-616 | 3-28-97 |

| GF-617 | 2-28-327 |

| GF-618 | 3-28-557/ 3-28-267 |

| GF-619 | 6201 |

| GF-620 | 250-28-17 |

| GF-621 | 6-5-28-117 |

| GF-622 | 6-5-28-127 |

| GF-623 | 140-28-17 |

| GF-625 | 2-28-827 |

| GF-626 | 6-28-407 |

| GF-631 | / |

| GF-701 | / |

| GF-702 | / |

| GF-703 | / |

| GF-704 | / |

| GF-705 | / |

| GF-706 | / |

| GF-621 | 6-5-28-117 |

| / | 2-28-857 |

| / | / |

| / | / |

| / | 170-28-27 170-28-37 |

| / | / |

| / | / |

| / | / |

| / | 26-251 |

| / | 3-28-57 |

| GF-622 | 6-5-28-127 |

| / | 2-26-1977 |

| / | 2045028 |

| / | 2060028 |

| / | 26-177 |

| / | 6-28-347 |

| / | 5-28-627 |

| / | 26-253 |

| / | 26-272 |

| / | 2-28-577 |

| 2-28-417 |

| 352.410.0130 | 01-246C |

| 336.410.0030 | 01-377C |

| 336.411.0011 | 02-334 |

| 352.411.0011 | 3-2-1139 |

| 1672353 6885644 | 6-5-2-329 |

| 2.994.951 | 2-2-479 |

| 360.350.0045/ 327.350.0045 | 01-294C |

| 656.411.0011 346.350.1545 | / |

| 2994235 | 3-2-159 |

| CITT4866A 9298975 | 3-2-479 |

| 94.622.054 | 4-2-669 |

| 41251-98003 | / |

| 93163687 A000.411.0645 | 250-2-15 |

| A00.041.10745 | 250-1-15 |

| 3319737/6885181 83704900 9299121 | 2-2-879 |

| 3731598002 | / |

| 3.731.598.001 | / |

| / | 3-2-1339 |

| 839.984.00 | 2-2-1339 |

| 261950 | 02-338 |

| 806.339.00 / 841.368.00 | 3-2-1159 |

| / | / |

| / | / |

| / | / |

| / | / |

| / | / |

| / | / |

| / | / |

| / | / |

| 1523280/ 1523282 | 01-342 |

| 360.350.0445 | 01-379 C |

| 360.350.0645 | / |

| 335.410.0130 | / |

| 346.350.0445 | / |

| 385.353.1245 | / |

| 6.885.168 | 01-310 |

| 382990/ 382991/ 1110071 | 01-315 |

| 000.262.2645 | / |

| 000.411.1345 | 140-1-15 |

| 383.282.0245 | / |

| 383.282.0445 | / |

| 345.282.0045 | / |

| 2TB.525.283 A | / |

| 931.631.24 | 70.619 |

| 931.920.46 | / |

| 6.885.657 | 01-339 |

| 6.885.148 | 01-517 |

| 1.672.362 | 01-302 |

| 695.353.0145 | / |

| 1.672.275 1.523.382 | / |

| 1.524.358 1.523.262 1.523.263 | / |

| 346.350.1645 | / |

| 346.350.0545 | / |

| 346.350.1445/ 942.350.0045 | / |

| 942.353.1045 | / |

| 394.410.0130 395.410.0130 | 01-524 |

| 970.262.1045 | / |

| 693.350.0045 | / |

| 355.353.0545 | / |

| 385.350.0145/ 385.353.0145 | / |

| / | 3-1-4671 |

| 20.706.812 | / |

| 20.706.913 | / |

| 1.622.790 8.172.618 | / |

| 000.264.4245 | / |

| 368.411.0111/375.411.0011 395.411.0211 | / |

| 6.885.567 1.199.4933 | 02-370 |

| 386.410.0030 | 02-418 |

| 395.411.1811 | / |

| 364.411.0011 | / |

| 335.411.0211 | / |

| 000.410.0730/ 385.411.1811 | 02-441/ 02-437 |

| 385.411.1711 | / |

| 6.885.155 | 02-266 |

| 6 .885.154 67.529 | 02-206 |

| 6.885.650 | 02-267 |

| 7.111.000 | 02-268 |

| 352.411.0211 | 02-245 |

| 000.411.0545 | 170-2-45 |

| 8127.229 | 170-2-35 |

| / | 2-2-1329 |

| / | 3-2-1299 |

| / | 2-2-329 |

| / | 4-2-1069 |

| / | 140-2-25 |

| 000.410.0830 | 6-5-2-419 |

| 3.618.855 B7T.4866 A 7.322.435 503.529 | 3-2-559 |

| 373.1598.001 | 3-2-119 |

| 656.411.0311 | 5003993 |

| / | 2-2-1679 |

| / | 5001903 |

| / | 2-2-489 |

| 1.651.247 9.316.3687 | / |

| 20471436 9.319.2010 | 2060002 |

| / | 2-2-1459 |

| / | 3-2-1329 |

| 500-1905 | / |

| 344.410.0108/ 344.410.0188 | 03-339XS |

| 335.410.0308 | 03-423XS |

| 600.600.907.3007 | 3-3-118KX1 |

| 3.707.216 | 3-3-1481KX |

| BC2T4841A T11.521.353 9.307.587 | 3-3-1601KX1 |

| 2RD521353/ BC8T4841A | 3-3-788KX/ 3-3-788KX1/ 3-3-788KXS |

| 600.300.900.6006 BD2Y-4841A | 03-336XS/ 2-3-14491KX/ 2-3-14501KX |

| / | 03-514XL |

| 384.410.0008 TE3 521 353 88HU.4841AA 88TU.4841AA 93.276.293 | 5-3-2261KX |

| 173766 | 03-334XL2 |

| 207989 | 03-541XL |

| BFOX-4841A TMJ.521.353 2ZO.521.131 BF1X4841C | 6-3-2651KX |

| 2UU.521.353 BF5X-4841A | 6.5-3-1371KX |

| 695.410.0008 85HU-4841A/ BF1X4841A | 4-3-1241KX |

| TAAM-4841A 7.322.139211.501.382-1 | 2-3-1421KX/ 2-3-1421KXS |

| BC8Y4841A 2.994.948 | 2-3-128KX2/ 2-3-128KXS/ 2-3-128KX1 |

| 2TG521353 695.410.0008 | 90-3-21X |

| 2994940 | 03-312XS/ 3-3-7071KX |

| 690.410.0108 | 3-3-2041KX |

| / | 3-3-7071KX 03-312XL1 |

| 2RO521131 4128595 TL1521353 | 3-3-1601KXS/ 3-3-1601KX1 |

| 37373-98001 | / |

| 52289713 | 2-3-9791X |

| / | 6.5-3-1351KX |

| 501207713 CQ43008 | 250-82-31X |

| / | / |

| DQ29377 0095236010 81109800 | / |

| 3604080 0095236013 81109600 DQ29376 | / |

| 34026 800910349002 81343500 84996792/ 9579339 DQ28541 | / |

| 34025 8009103489004 84996793 DQ28542 | / |

| / | 2-3-8001 |

| / | 2-3-8021 |

| 335.411.0605 | / |

| 345.411.0005 | / |

| 6.885.157 1.199.4930 | 03-386 XL1 |

| 3.716.646 | / |

| 2S0.521.131 T11.522.135 85HU.4841A 94.625.916 | 4-3-1241 KXS |

| T2D.521.353 7.322.139 BF1X.4841A 9021-2150-1700/08 | 4-3-1241 KX1 |

| T2D.521.353B | 03-462XS |

| 67.546 6.885.156 1.199.3923 | 5-3-2341 KX2 |

| 9.298.887 | 03-346X |

| / | 2-3-14371X |

| / | 03-542XL |

| / | 5001906 |

| 04-134 | |

| 6-5-3-1371KX | |

| SL-45 | |

| 03-423XS | |

| 9298887 | 03-346X |

| 1358013 | |

| 5-12072X | |

| 5-12072X | |

| 3716646 | 3-3-3231KX |

| / | 3-40-1901 |

| / | 3-53-1881 |

| 358.411.0002 | 40-1445 |

| 344.410.7001 | 54-442 C1 |

| 335.411.0102 | 54-556C |

| / | 4-40-761/ 53-484 |

| 384.410.0208 | 5-40-1051 |

| / | 6-40-621 |

| 6.885.642 | 6.5-40-191 |

| / | 8-40-101 |

| 208074 | 40-1723 |

| / | 250-53-11/ 250-53-31X |

| / | 5-53-271/90-53-11 |

| 688.411.0102 | 3-40-1571 |

| 169110/ 1673460 | 40-1722 |

| / | 3-53-451 |

| / | 4-53-61 |

| 335.411.0002 | 40-1560 |

| / | 53-400/3-53-1371 |

| / | 3-53-1361 |

| 690.411.0002 | 53-1443 |

| 6885588 | 54-458 |

| / | 40-1408 |

| / | 90-40-11 |

| / | 2-40-2431 |

| / | 2-53-501 |

| / | / |

| BC8A4551A | 2-40-22-71 |

| / | 3-53-1821 |

| / | 4-53-341 |

| / | 4-53-541 |

| / | 250-53-11/250-53-31X |

| 208086 | 54-470 |

| / | 140-53-11 |

| 177103 | 54-435 |

| / | 6-53-421 |

| / | 2-40-1521 |

| / | 2-40-1701 |

| / | 2-40-1851 |

| / | 6-5-40-191 |

| / | 6-5-40-201 |

| / | 8-40-101 |

| / | 53-433/53-1433 |

| / | 40-1603 |

| / | 4-53-521 |

| / | 54-736 C |

| / | 90-40-11 |

| 345.411.0002 | / |

| / | 53-484 |

| 177.103 | 40-434 |

| / | 54-417 |

| 1.105.348 | / |

| / | 54-677 |

| / | 6-5-53-51 |

| / | 6-5-53-91 |

| / | 40-1490 |

| 6-40-541 | |

| 3-53-2441X |

| 000.410.0436/000.410.0430 | 04-852-1 |

| 000.410.1630 | 250-4-871-1 |

| 000.410.0330 | 3-4-3091-1 |

| 4460311 2VF.521.511 4.480.311 | 4-4-6031-2/ 4-4-6031-1 |

| 88HU4865AA/ TE3521211 | 5-4-7171-1 |

| 87H7-7089AA | 04-769-2 |

| . TN4 311 963 | 4-4-6161-2 |

| / | 4-4-5301-02 |

| / | 04-898-1 |

| / | 3-4-11831-2 |

| 52270198/ 94636750 | 4-4-2051-1 |

| / | / |

| 202.382/208.382/ 208.513 | 04-360C |

| / | / |

| 190027/202805 | 04-178C |

| / | 41-114 6-4-7147-1 |

| 000.411.0930 | 140-4-1381-1 |

| 90-4-11-1 | |

| 3-4-3091-1 | |

| TMJ.525.283 TAK.525.283 | 070.492 070.493 |

| 87HU.4851 CA 52.250.214 T16.525.283 | 4-4-6171-2 070.386 |

| TE3.525.283A 7.149.146 000.353.1045 | 5-4-7841-1 070.431 070.068 |

| 000.353.0145 | 70.068 |

| TMG.525.283/6112009098002 | 6-4-7721-1 070.449 |

| 2RG.525.283 | 90-4-311-1 070.457 |

| 000.353.0145 | 04-912-1C 100.4.1301-1 |

| 3.313.301 | / |

| 2TG 521 211 93.276.288 | 90-4-11-1 |

| 2RG.525.283 87HU.4851AA 52.287.489 | 4-4-6182-2 |

| T12.525.283A 87HU.4851BA | 3-4-11241-2/ 3-4-7541-2 |

| 2TD.311.963 BS5T.7089AA 086903/ 2RH 311 963 | 4-4-6151-1 |

| 85HU.7089/B94646126 | 4-4-5301-1/ 4-4-5301-2/ 04-952-1 |

| BD7T.7089A 77TU.7089A T11.311.963 | 04-746-1 |

| BD2T.4851A 9.298.971 T95.311.807 | 04-179/04-179-1 |

| 386.353.7045 | 04-856-1 |

| 384.353.7045 | 04-857-1 |

| 384.353.7145 | 04-915-1 |

| 694.353.7045 | 04-895-1 |

| 83TU.4851A 94.646.123/135 T2D.525.283 | 04-679-2 |

| 94.646.124 T2D.311.807A | 04-679-1 |

| BG2X.7089AA 2TG.311.963 | 500-3992 |

| E7H2.7089J 7.149.028 | 5-4-6321-1 5- |

| BF1X4865A 503.353.876 | 6-4-7141-1 |

| 87HU.4851DA T14.525.283 | 70.418 |

| 695.352.0044 664.353.7045 | 04-869-1 |

| 695.353.7045 695.352.6644 | 140-4-1281-1 |

| 90HU.485.1AA TAE.525.283A | 70.438 |

| CITT.4865B 9.298.998 | 3-4-3091-1 |

| 000.262.3448 | 04-896-1 |

| 694.262.7045 | 04-897-1 |

| 78TU.7089A 94.642.778 BE2Y.1089A TO6.311.963 | 04-590-1/ 04-590-2 |

| 000.264.7945 | 04-879-1 |

| 384.282.7045 | 04-860-1 |

| BG5X.4851CA 2UO.525.283 | / |

| 2UO.525.283A | / |

| BG5X.4851AA 2UO.525.283B | / |

| BF5X.4851AA 2RR.525.283 | / |

| 2T2.525.283 | 250-4-341-1 |

| BF5X.4851A 2TO.525.283 | 6-5-4-3721-1 |

| TJG.311.963 2RS.311.963 | 86.749 |

| / | 6-5-4-1891-1 |

| BH1X.7089-AA 503.356.411 2UO.311.809 | 550-5543 |

| BG3X.7089.BA 20.750.572 | 550-5547 6-5-4-4631-1 |

| 234.084 | 04-637 C |

| 1.676.722 | 04-874-1 |

| 1.308.761 | / |

| 385.984 | / |

| 385.984 | / |

| 385.984 | / |

| 111.661 390.237 1.325.900 | / |

| 000.410.1230 | 04-887-1 |

| 696.350.0045 | 250-4-591-1 250-4-721-1X |

| BG2X.7089AA 503.355.996 2TB. 311.963 | 86.746 |

| A3260V1894 | / |

| A3260K1909 | / |

| 693.353.7445/ 693.350.0144 | / |

| 976.262.0845 | 140-4-1411-1 |

| 970.262.1445 | / |

| 550-5527 | 90-4-371-1 |

| 688.350.7045 | 04-792-2 |

| 688.350.7145/ 688.353.7145 | 04-794-2 |

| 688.350.0144 | 04-878-1C |

| 688.262.7745 | 04-833-1 |

| 693.353.7145 | 04-823-1 |

| 2T0311809 | / |

| 2T2311809/000.264.4245 | 250-4-581-1 |

| 634.352.0044 | / |

| 234084 | 04-637C |

| 04-915-1 |

What People are Saying About Us?

FAQ about Our Commercial Truck Steering Joint

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

- Check whether the product pictures are consistent.

- Also, verify that the product OE or standard primary manufacturer number is correct.

- Then, check if the applicable model and year are accurate.

- Finally, check if the product length and mounting dimensions are correct.

- Accurate factory price, no intermediary.

- We have our forging plant, and we make all forging roughs ourselves, which means we have a more significant cost advantage than others.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity for the steering joint is 100 pcs, and for the steering shaft, the minimum order quantity is 50 pcs.

Yes, we offer free samples for your test.

All products from 1A Steering Shaft are covered with a 12 Months warranty from the date of installation or 18 Months warranty from the shipment date, whichever comes earlier.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Usually, for old products, the lead time will be less than 45 days; for newly developed products, the lead time will be 60 days.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, the brand colorful package service is our leading service; it contains laser marking your logo on the product surface or roughs, printing your brand colorful bag, printing your brand labels, make your brand colorful box and cartons.

Our brand-colorful package service is the perfect way to ensure your product stands out in the market. We offer a wide range of customizations that can help you get the most out of your product. Our team specializes in laser marking, which allows us to place your logo or design onto the surface of any product with precision and accuracy.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

Who paid for the mold, and who owns the mold.

Send Us Your Inquiry Now!

Please fill out the form on the right to send us an inquiry. We always want to ensure that our customers get the best deal, so let us know what you’re interested in, and we’ll get back with a quote!