Trusted Center Support Factory

"JIUREN AUTO PARTNER" Company Overview

Yuhuan Jiuren Machinery Co., Ltd was founded in 2008 and is a professional manufacturer of steering shafts, drive shafts, and axle shafts. Specialized solutions for cars, trucks, agricultural machinery, and UTVs.

We provide OEM, ODM, and custom services; our products are mainly exported to the USA, Canada, Mexico, Brazil, Argentina, Peru, Australia, New Zealand, Germany, France, the UK, Italy, Netherlands, Poland, Russia, Ukraine, Spain, Hungary, Turkey, Saudi Arabia, Malaysia, Thailand, etc.

In the automotive field, our producta are mainly for Toyota, Honda, Nissan, Mitsubishi, Lexus, Suzuki, Isuzu, Mazda, Daihatsu, Subaru, Infiniti, Mercedes-Benz, BMW, Audi, Volkswagen, Volvo, Porsche, Jeep, Ford, Lincoln, Dodge, Chevrolet, Buick, Cadillac, Chrysler, Hummer, GM, Kia, Hyundai, Land Rover, Jaguar, Renault, Fiat, Peugeot, Opel, Lada, UAZ.

In the truck field, our products are mainly for Mercedes-Benz, Scania, Volvo, Iveco, DAF, Volkswagen, Ford, dump trucks, Basculantes, etc.

In the agricultural machinery field, our products are mainly for John Deere, Case IH, Kubota, New Holland, etc. In the UTV field, our products are mainly for Polaris and Can-Am. Etc.

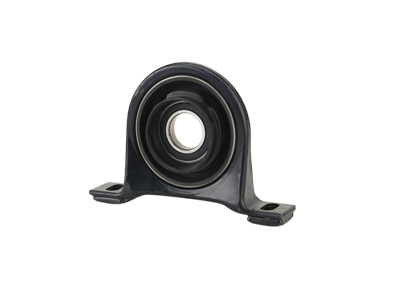

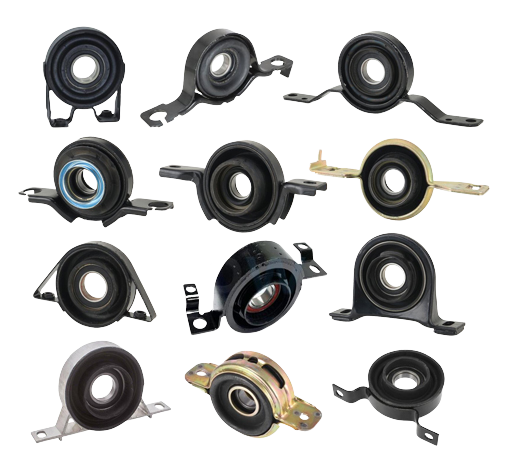

Featured Drive Shaft Center Support in The Market

What is a drive shaft?

- The propeller shaft, also known as the drive shaft, is an important component of a car’s drivetrain. It transfers power from the engine to the differential gearbox, which in turn drives the wheels and propels the vehicle forward.

- The propeller shaft comes in different lengths depending on its use. Longer propeller shafts are used for rear-wheel drive vehicles, while shorter propeller shafts are used for front-wheel drive vehicles.

- The propeller shaft is typically made of a steel or aluminum alloy and must be properly balanced to ensure smooth operation and avoid vibration during use. Proper maintenance of this component is essential to keep your car running smoothly and reliably over time.

- Overall, the propeller shaft plays an integral role in the operation of a car. It is responsible for transferring power from the engine and ensuring that the vehicle runs smoothly over time. Without it, your car could not drive properly or reliably. That is why it is important to ensure that you maintain your propeller shaft in good working condition.

How to classify the drive shaft according to the drive form?

The drive shaft of an all-wheel-drive (AWD) vehicle:

1 . A heavy-duty, high strength construction that can withstand the torque generated by all four wheels.

2 . A two or three piece design for ease of installation and maintenance.

3 . Sealed joints to protect against dirt, dust and other contaminants.

4 . Universal joint angles and splines to help accommodate suspension geometry changes.

5 . Balanced to minimize vibrations.

The drive shaft of a four-wheel-drive (4WD) vehicle:

1 . A double or triple cardan construction to support the transfer of power from one axle to the other.

2 . High strength materials and components to withstand high loads generated by each wheel.

3 . Constant velocity joints for smooth, quiet operation.

4 . Slip yokes to improve driveline angle changes.

5 . Sealed joints for protection against contaminants.

The drive shaft of a rear-wheel-drive (RWD) vehicle:

1 . A single-piece construction with universal joints on either end to accommodate suspension geometry changes.

2 . High strength materials and components for efficient power transfer.

3 . Sealed universal joints for protection against contaminants.

4 . Balanced to reduce vibrations.

5 . Slip yoke for improved driveline flex and angle changes.

What Parts Make Up the Drive Shaft?

The following are drive shaft components and the materials typically used for each element.

01. Yokes – include flange yoke, slip yoke, tube yoke, and end yoke; these yoke is forged or cast, and the material is 45#.

02. Universal joint – It is one of the essential parts of the drive shaft. It provides a flexible mechanical connection between two parts, allowing them to move around each other while transmitting torque. This connection creates a more efficient and reliable power transfer over an extended distance than traditional rigid methods.

- The body material is 20Cr; roughs are usually forged or cold extruded.

- The needle-bearing material is GCr15.

- The bearing cup material is 20#.

- The grease seal material is NBR.

- The snap spring material is 65Mn.

03. Tube shaft and midship shaft – The shafts material is 40 Cr.

04. Tube – Usually, the tube material is 20#.

05. Center bearing – Its a important part of a drive shaft. The main material is Natural Rubber, 45#, and bearings.

Drive shaft experimental testing equipments

- 1. Drive shaft torque tester

Test if the static torque level of the drive shaft can meet the industry standard.

- 2. Drive shaft balancing machine

Each of our drive shafts is dynamically balanced before leaving the factory to ensure that the unbalance of each drive shaft is less than 5 grams.

- 3. Drive shaft center support rubber stress tester.

Many of the drive shaft runout problems are caused by insufficient rubber stress on the center support, we have developed this tester to avoid this problem on our drive shafts.

- 4. Tensile Strength Tester.

Test the drive shaft bolts for compliance with industry standards for tensile strength ratings.

- 5. Hardness Tester.

Test the hardness of each component of the drive shaft to meet industry standards.

- 6. Metallographic Analyzer.

A Metallographic Analyzer is an instrument used to visually assess the microscopic structure of a metal sample. It enables users to determine the grain size and distribution, as well as measure hardness, toughness, ductility and strength properties of the material. Through this analysis, metallurgists can evaluate various aspects such as heat treatment effects, casting defects or physical properties in order to determine the most suitable application for any given metal.

- 7. Rubber Ozone Tester.

Rubber parts are important components on the drive shaft, and the ozone tester can test whether the performance of rubber in different use environments can meet industry standards.

Drive shaft package

- 1. Customized Services

Each drive shaft can have your brand logo engraved on the product using laser engraving according to your needs.

- 2. Customized brand label

We can provide you with custom brand labels.

- 3. Super thick honeycomb packaging box

Our driveshaft packaging uses a thickened honeycomb box with a thickness of 1.5cm on one side and an internal plus middle support to better protect your product from damage during shipping. And the honeycomb box packaging is both beautiful and classy, which can perfectly fit your brand.

- 4. High quality anti-rust paper

The unpainted side of each driveshaft is coated with high-grade anti-rust oil and wrapped with high-quality anti-rust paper, which is both aesthetically pleasing and provides excellent rust protection.

- 5. International standard fumigation-free pallets

For orders with smaller quantities, we will use international standard fumigation-free pallets to provide a second layer of protection for your drive shaft as well as the box to avoid damage to the product and the box during transportation.

- 6. Loading containers

For the batch of larger orders, in order to save container space, generally will use the bulk goods directly loaded containers, regular honeycomb box orderly discharge more space-saving and very beautiful.

| 601 410 17 10 601 410 15 10 601 586 00 41 601 410 04 10 |

| 601 410 17 10 601 410 15 10 601 586 00 41 601 410 04 10 |

| 124 410 06 81 124 410 01 81 |

201 410 05 81S |

| 26 12 1 226 723 26 12 1 225 774 26 12 1 226 415 |

| 210 410 18 81 210 410 12 81 |

| 202 410 03 81 202 410 03 81S 202 410 05 81 202 410 05 81S 202 410 058 1S1 |

| 901 411 03 12 901 411 04 12 2D0 598 351 2D0 521 351 |

| 26 12 7 513 218 |

| 26 12 1 226 731 26 12 1 229 089 |

| 2E0598351C 906 410 03 81 |

| 906 410 02 81 |

| 26 12 1 229 726 26 12 7 507 740 |

| 26 12 1 229 492 26 12 7 501 257 |

| 639 410 06 81 |

| 639 410 04 81 |

| 203 410 21 81 |

| 203 410 19 81 203 410 19 81 S1 |

| 203 410 24 81 |

| 203 410 20 81 |

| 203 410 20 81 |

| 124 410 02 81 124 410 07 81 |

| 202 410 04 81 |

| 460 410 02 22 460 410 00 22 |

| 211 410 01 81A |

| 26 12 7 526 631 |

| 26 12 7 521 855 |

| 26 12 2 282 496 |

| 26 12 7 521 856 |

| 2044102481 |

| 26 12 1 225 152 26 12 1 225 152S |

| 2054108501 |

| 26127564695 |

| 26 12 7 526 632 |

| 26127558745 |

| 4060617 6635542 7239265 4104708 95VB4826AA 99VB4826AB YC1W4826BC |

| 6649122 92VB4826BB |

| 26 11 1 227 410 |

| 26 11 7 511 454 26 11 1 209 168 26 11 1 227 420 |

| 26 11 7 610 061 26 11 7 605 629 26 11 7 546 425 |

| 7LO 521 403 7L6 521 403 |

| 26 11 7 542 238 |

| 26 11 7 573 276 26 11 7 507 328 26 11 7 512 619 |

| 26 11 7 518 443 |

| 26 11 7 503 159 |

| 203 411 00 15 |

| 205 411 00 00 |

| 26 11 7 610 372 |

| 26 11 1 229 360 26 11 1 227 717 26 11 1 229 080 |

| 26 11 7 546 426 |

| 26 11 7 522 027 |

| 1K0 521 307A |

| 170 410 00 15 129 410 00 15 202 410 09 15 202 410 19 15 210 410 08 15 |

| 210 411 04 15 |

| 116 411 02 15 115 411 09 15 116 411 01 15 |

| 124 411 06 15 124 411 01 15 202 410 03 15 |

| 205 411 01 00 115 411 09 15 116 411 01 15 |

| 240 411 01 15 221 411 01 15 906 411 02 00 |

| 126 411 02 15 107 411 00 15 107 411 02 15 |

| HB206FF 210527X |

| HB88107 211139X |

| HB88508 2101391X |

| HB88509 210969X |

| HB88510 210121-1X |

| HB88512 210661-1X |

| HB88107A 211187X |

| HB88107B 210088-1X |

| HB88107C 210090-1X |

| HB88107D 210367-1X |

| HB88108D 211848-1X |

| HB88508A 211083X |

| HB88508AA 210873-1X |

| HB88508AB 210866-1X |

| HB88508B 210433-1X |

| HB88509A 210084-2X |

| HB88509B 211172-1X |

| 5003323 210661-1X |

| HB88530 |

| HB88536 |

| 95VB4826AA 4060617 |

| 8C114826AA |

| 92VB4826BB |

| 83BG4826AB |

| 293521351 |

| 88107RB |

| 88508RB |

| 88509RB |

| 88510RB |

| 88512RB |

| 88107RB-G |

| 88508RB-G |

| 88509RB-G |

| 88510RB-G |

| 88512RB-G |

| TOQ000040 |

| 37230-22110 |

| 37230-12050 |

| 37230-22042 |

| 37230-22070 |

| 37230-35030 |

| 37230-35070 |

| 37230-35090 |

| 37230-35120 |

| 37235-35011 |

| 37230-35080 |

| 37230-36140 37230-36H00 |

| 37230-36080 |

| 37230-22190 |

| 37230-26020 |

| 37230-38010 |

| 37230-24010 |

| 37230-OK050 |

| 37230-30022 37230-40031 |

| 37230-42010 |

| 52380-42082 52380-42020 52380-42050 |

| 37230-OK021 37230-OK011 |

| 37230-20130 |

| 37230-29015 |

| 37230-30170 |

| 37230-30040 |

| 37230-34010 |

| 37230-35040 |

| 37230-35013 |

| 37230‐BZ010 |

| 37230-87302 |

| 37100-87402 37100-87403 |

| 37100-87Z01 |

| 8-94222-972-0 |

| 8-94328-799-0 8-97942-878-0 |

| 8-94328-800-0 8-97942-876-0 |

| 5-37516-006-0 |

| 5-37516-005-0 |

| 9-37516-030-0 |

| 1-37510-105-0 |

| 1-37516-048 |

| 49710-45200 |

| 49710-5A020 |

| 49130-4A000 |

| 49575-2E000 49575-2E400 |

| MC824412 |

| 12019-25403 |

| 12019-25403 |

| 12019-28000 |

| MB000076 MB000078 |

| MB000083 |

| MB563234 |

| MB154199 |

| MB000076 |

| MC830615 |

| MB563204 |

| MB154080 |

| MB000815 |

| MB505379 |

| MB154086 |

| MR580647 |

| 37521-33G25 37521-56G25 37521-32G00 |

| 37521-34G00 |

| 37521-01W25 |

| 37521-W1025 |

| 37521-Q0125 |

| 37521-41L25 |

| 37521-JR60A |

| 37521-33P25 |

| 37510-90110 37518-90019 |

| 37230-1230 |

| 37230-1290 |

| 37230-6213 |

| P030-25-310A P030-25-310C |

| P047‐25‐310A P65-25-310A |

| SA02-25-310 SA04-25-310 |

| SA68-25-300A |

| 6394100618 |

| 3104100822 3094100110 3095860141 |

| 9014110312 9034100010 9014110310 |

| 9014110312 9014110412 9014100310 A200598351 |

| 6014101710 |

| 6014101710 |

| 6844104022 0004100722 |

| 6114101710 6114102110 |

| 3184101522 |

| 3464100010 3814101522 3814100920 |

| 3854100722 3854101722 3854101622 9734100022 |

| 3954100222 3814100222 |

| 3854100922 |

| 9064100581 9064101181 |

| 9064100581 9064100581SK 9064100781 9064101781 |

| 6704110112 |

| 9734110112 |

| 9734110012 9734110112 |

| 6544110012 |

| 6564110012 6564110212 0004101010 |

| 4604100022 4604100910 4604100222 |

| 6544100022 6204100022 3894100222 3894100122 A3894100222 |

| 3954100622 3954100022 6554100022 6204100010 |

| 6594110112 |

| 3954100622 3954100022 6554100022 6204100010 |

| 3454100051 |

| 0003250496 0003250696 0003250896 |

| 0003250596 0003250796 |

| 81394106010 |

| 81394106013 81394106017 |

| 81394106019 |

| 81394106020 81394106032 |

| 81394006107 |

| 81394106021 |

| 81394106031 81394106033 81394106023 81394006105 |

| 81394106018 |

| 3952036 3953472 |

| 1070171 1697203 20362601 20845657 |

| 1068208 20471422 |

| 1696389 6212888 263000 |

| 16229553 263567 8171366 |

| 1651230 263006 |

| 20471422 |

| 20362600 |

| 21026452 |

| 20471428 1068222 |

| 1629553 8151413 20390836 |

| 608924 |

| 541791 |

| 1404554 |

| 1404560 |

| 1700326 |

| 1408525 1409221 1409235 |

| 1252249 1298157 |

| 102203 |

| 1409056 1782199 |

| 12568011457 |

| 1288235 |

| 102204 555364 |

| 1435557 1288220 1323765 1288120 |

| 1779697 1288120 1323765 1435557 |

| 1235569 0678426 701756 |

| 1288242 |

| 1364376 1288231 1425157 |

| 189461 |

| 1113031 1403663 |

| 294270 |

| 1387764 |

| 9984261 9932698 4390495 92536526 |

| 93160324 42536726 |

| 93160324 |

| 93163376 |

| 42536965 5687637 93160223 4682902-B 6455173 994167 |

| 42554407 42561251 42565254 42530546 42561251 |

| 994167 989085 42532794 4655173 4687637 |

| 93158202 |

| 42536523 4682902 42534452 |

| 93156460 42538439 93157025 |

| 4614631 4639052 4622213 93160226 |

| 93158251 |

| 4765836 4503320 |

| 42532291 42538366 |

| 4674953 93163091 4690354 |

| 8194600 42536524 93160517 |

| 42541440 93163091 |

| 2483546 |

| 42002123 |

| 42532295 42538367 |

| 93157125 |

| 93157125 |

| 93191989 4803933 4473133 42077882 41932125 42541438 42002125 |

| 93157626 42536961 |

| 93194978 |

| 42087542 42541437 701756 42536963 93163689 93190884 |

| 93163689 |

| 93192572 42538361 |

| 5000560295 7701034294 7701034902 |

| 5000242914 5000821936 |

| 5000287986 |

| 5000589888 G.210-G.230 G.260-G.290 |

| 5000820884 5000876246 5000807211 |

| 5000819188 |

| 5000816926 5000816927 5000816925 5000815989 5001020496 |

| 5000819211 0003997101 |

| 3302-2202085 |

| 3153-2204076 |

| 3535730 |

| 5336-2202085 |

| 5336-2202085 |

| 63031-2202086 |

| 53A-2202081 |

| 5336-2202086 |

| 40520-S10-003 |

| 40520-S9A-901 |

| 40100-TIE-E01 40100-SWA-A01 40100-P0A-P02 40100-SWA-A91 |

| 37100-48030 |

| 49100-4H000 49100-4A970 |

| 55222107 |

| 49300-2B500 |

| 49130-4A400 |

| 37100-42090 |

| 30713272 31256270 30713272 8689886 |

| 30735566 30783365 30787839 31256001 |

| 68006637AA |

| 5104083AA |

| 5273310AA |

| 4L344K145SD |

| 91-00835 N 7E534357AH 7E534K357AE 7E534K357AF 7E534K357AG 7E5Z 4R602-A |

| 8L3Z4602D |

| 212030-1X |

| 3401A022 |

| 37522-W1625 |

| 27111-AG12A |

| 27111-AE100 27111-AE101 27111-AE102 27111-AE17A |

| 27031-FA020 |

| 37100-48030 |

| 0446073 |

| 27031-FC030 |

| 27031-FC000 |

| 27111-AE110 |

| 27111-AE061 27111-AE060 27111-AE060 |

| 27111-FE130 |

| 320003602R 370002820R 8200945335 |

| 27111-FG020 27111-FG021 |

| TVB500380 |

| TVB500390BRG TVB500390 |

| TVB500360 |

| 40100THCH010M1 |

| 8K0521101G 8K0521101N 8K0521101AA |

| 52123627AA |

| 4B0521106D 4B0521106F |

| 27031-FA140 |

| 27111-AG05A |

| 40100S-ZAA01 40100S-ZAA02 |

| 92194140 |

| 49100-3E450 49100-3E400 |

| 26101226417 |

| 26111226439 |

| P52123612AD |

| 49100-3E951 |

| 27031-FC030 27111-SA030 |

| 27031-FC000 27031-FC001 |

| 27111-AE062 |

| 27111-FG031 27111-FJ030 |

| 27111-SC021 |

| A6394107006 A63941101916 |

| A6394103306 |

| A1644103102 |

| DT4Z4R602A |

| 639410048 6394100081 |

| 370002820R |

| 33200-08000 |

| 345.410.0051RB |

| BC0043 |

| 0755-25-300 |

| 8-97131-143-1 |

| 8-94328-799-0SA |

| 1000008900022 |

What People are Saying About Us?

FAQ about Our Drive Shaft

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

- Check whether the product pictures are consistent.

- Also, verify that the product OE or standard primary manufacturer number is correct.

- Then, check if the applicable model and year are accurate.

- Finally, check if the product length and mounting dimensions are correct.

- Accurate factory price, no intermediary.

- We have our forging plant, and we make all forging roughs ourselves, which means we have a more significant cost advantage than others.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity for the steering joint is 100 pcs, and for the drive shaft, the minimum order quantity is 50 pcs.

Yes, we offer free samples for your test.

All products from Jiuren are covered with a 12 Months warranty from the date of installation or 18 Months warranty from the shipment date, whichever comes earlier.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Usually, for old products, the lead time will be less than 45 days; for newly developed products, the lead time will be 60 days.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, the brand colorful package service is our leading service; it contains laser marking your logo on the product surface or roughs, printing your brand colorful bag, printing your brand labels, make your brand colorful box and cartons.

Our brand-colorful package service is the perfect way to ensure your product stands out in the market. We offer a wide range of customizations that can help you get the most out of your product. Our team specializes in laser marking, which allows us to place your logo or design onto the surface of any product with precision and accuracy.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

Who paid for the mold, and who owns the mold.

Send Us Your Inquiry Now!

Please fill out the form on the right to send us an inquiry. We always want to ensure that our customers get the best deal, so let us know what you’re interested in, and we’ll get back with a quote!