Trusted Steering Joint for Commercial Truck Factory

"JIUREN AUTO PARTNER" Company Overview

Yuhuan Jiuren Machinery Co., Ltd was founded in 2008 and is a professional manufacturer of steering shafts, drive shafts, and axle shafts. Specialized solutions for cars, trucks, agricultural machinery, and UTVs.

We provide OEM, ODM, and custom services; our products are mainly exported to the USA, Canada, Mexico, Brazil, Argentina, Peru, Australia, New Zealand, Germany, France, the UK, Italy, Netherlands, Poland, Russia, Ukraine, Spain, Hungary, Turkey, Saudi Arabia, Malaysia, Thailand, etc.

In the automotive field, our producta are mainly for Toyota, Honda, Nissan, Mitsubishi, Lexus, Suzuki, Isuzu, Mazda, Daihatsu, Subaru, Infiniti, Mercedes-Benz, BMW, Audi, Volkswagen, Volvo, Porsche, Jeep, Ford, Lincoln, Dodge, Chevrolet, Buick, Cadillac, Chrysler, Hummer, GM, Kia, Hyundai, Land Rover, Jaguar, Renault, Fiat, Peugeot, Opel, Lada, UAZ.

In the truck field, our products are mainly for Mercedes-Benz, Scania, Volvo, Iveco, DAF, Volkswagen, Ford, dump trucks, Basculantes, etc.

In the agricultural machinery field, our products are mainly for John Deere, Case IH, Kubota, New Holland, etc. In the UTV field, our products are mainly for Polaris and Can-Am. Etc.

Featured Commercial Truck Steering Joint in The Market

Mercedes Benz Scania Volvo Fiat commercial truck steering joint, 316.460.0057 / 344.460.7057 / 6.884.459 / HJU816

Mercedes Benz Volvo commercial truck steering joint, 000.460.0157 / 344.460.7057 / HJU946

Volkswagen Ford commercial truck steering joint, TAR415721A / TAR415-725 / HJU807 / 301035

Volvo commercial truck steering joint, 1.606.502 / 8189503 / 1326778 / 1001490 / HJU884 / 28-108

Mercedes Benz commercial truck steering joint, 000.268.1489 / 344.268.7189 / 345.268.7089 / HJU814 / 28-106

Mercedes Benz commercial truck steering joint, 344.260.8033 / 352.260.2133 / HJU815 / 28-107

All You Need to Know About Commercial Truck Steering Joint

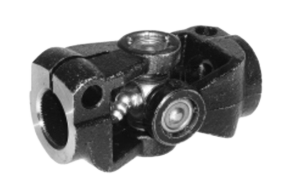

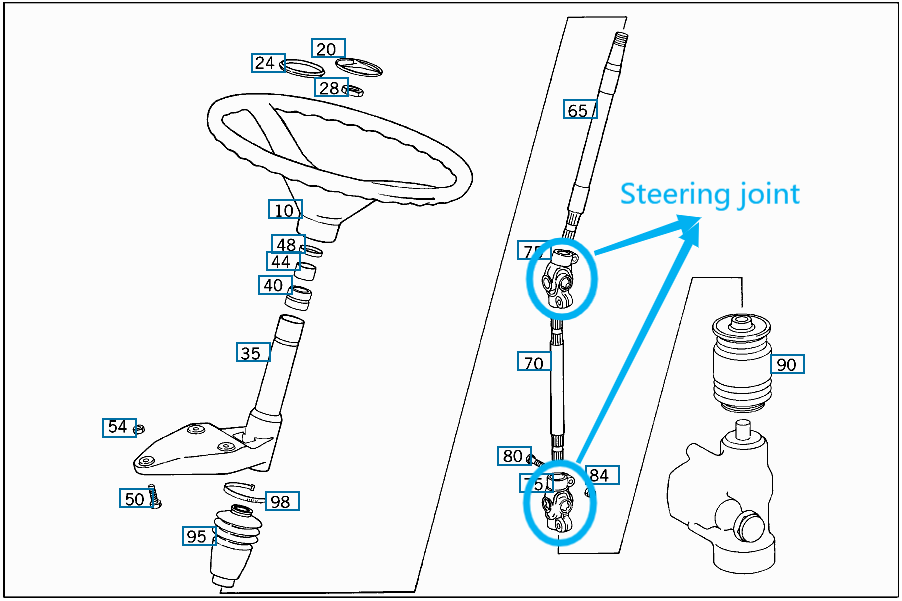

What is a Commercial Truck Steering Joint?

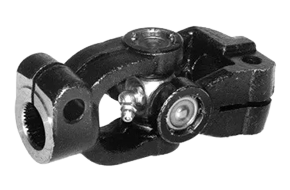

- A Commercial Truck Steering Joint also called a steering universal joint is a device used in commercial trucks for steering.

- It connects the steering column to the steering linkage, allowing it to move with the steering wheel and turn the front wheels.

- It also helps reduce wear on both parts and provides smoother handling.

- The joint consists of two metal plates connected by a ball-and-socket arrangement, which allows for smooth movement when turning. In addition, this design ensures an even distribution of force throughout the entire system, helping keep components from wearing out prematurely.

- Proper maintenance and lubrication are essential for keeping this part working properly, as failure can result in severe damage to the vehicle or injury to the driver.

- Overall, a commercial truck steering joint is essential to any commercial truck, helping ensure smooth and safe operation.

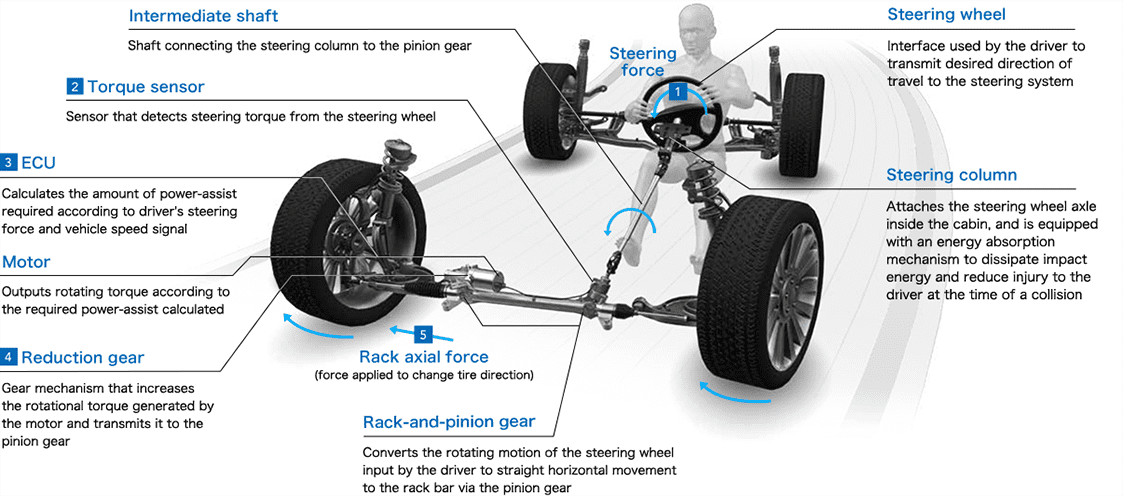

- Step 1: The steering wheel is rotated.

- Step 2: The torque sensor senses a torque signal, which is then processed by the ECU.

- Step 3: The ECU supplies an electric current to the motor based on the torque signal and the speed of the vehicle.

- Step 4: The motor's rotational torque is amplified by the reduction gear, before being sent to the pinion.

- Step 5: The torque generated by the pinion on the power-assist side (supplemental steering torque), as well as the torque from the pinion on the steering wheel side (steering rotating torque), is converted into a rack axial force to control tire direction.

What does the steering joint in Commercial Truck Use for?

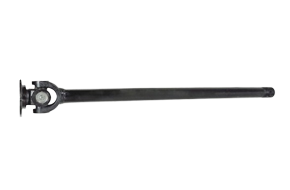

- The steering joint in commercial truck use is responsible for connecting the steering box to the front wheels, allowing them to turn.

- It converts rotary motion from the steering box into linear motion, allowing commercial trucks to change direction. As commercial trucks tend to be heavy and oversized, this joint plays a critical role in maneuverability and driver safety.

- The commercial truck’s steering joint must be properly maintained throughout its lifespan to ensure that it functions correctly and does not fail during operation.

- Commercial trucks will not have complete control over their maneuvering capabilities without proper maintenance, leading to an increased risk of collisions or other accidents.

- Therefore, qualified professionals specializing in commercial vehicle repair services should carry regular maintenance for commercial truck steering joints.

- By ensuring that your commercial truck’s steering joint is kept in top condition, you can maintain the optimal performance and safety of your commercial truck.

What Parts Make Up the Steering Joint?

The following are joint steering components and the materials typically used for each element.

01. Spline yoke – Usually, the head bore has splines to connect other parts; this yoke is forged or casting, and the material is 45#.

02. Universal joint – It is one of the essential parts of the steering joint. It provides a flexible mechanical connection between two parts, allowing them to move around each other while transmitting torque. This connection creates a more efficient and reliable power transfer over an extended distance than traditional rigid methods.

- The body material is 20Cr; roughs are usually forged or cold extruded.

- The needle-bearing material is GCr15.

- The bearing cup material is 20#.

- The grease seal material is NBR.

- The snap spring material is 65Mn.

What are the Technical Standards for Each Component?

Commercial trucks generally carry heavy loads, requiring high-performance standards for each component. The following are the technical requirement standards for each commercial truck steering joint component.

01. Spline yoke – The torque requirement is 300 Nm, so it has high requirements for the rough, which has to be forged, followed by the cast. Our yoke torque can generally reach over 500 Nm.

02. Universal joint clearance – Universal joint clearance requirement is less than 0.03-0.05mm. Our universal joints are made of the “Wanxiang” brand, and the clearance is generally lower than 0.02mm.

03. Screws and nuts – Screws and nuts are also essential parts, screws require 10.9 class strength screws, and nuts require 8 class strength nuts. Screws and nuts require a torque of 120 Nm or more after locking. Our screws use class 10.9, and our nuts use class 8. The torque can generally reach 150 Nm or more after locking.

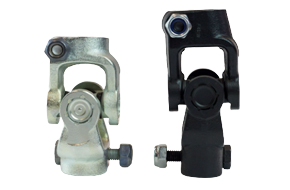

What Are The Types of Commercial Truck Steering Joints?

Because of the large load characteristics of commercial trucks and dump trucks, their steering joints require high torque and strength, which makes only forged roughs the most suitable, followed by cast roughs.

Forged Steel yoke

Forged yokes are the most widely used in automotive and truck steering shafts.

Because it has the highest material density, the best torque performance, is wear-resistant and durable, and is not easy to deform, this yoke will generally be used in middle and high-end passenger cars, SUVs, trucks, and agricultural machinery.

Casting Steel yoke

Casting yoke material density and performance can not be compared with forging yoke, but in the shape of the yoke, casting has more advantages than forging; casting can make a variety of shapes, not limited by the shape. But sometimes, the surface of the casted yoke will have air holes and sand holes.

So it is generally used for American cars, like Jeep, Ford, Lincoln, Dodge, Chevrolet, Buick, Cadillac, Chrysler, Hummer, GM, etc.

How Many Types of Surface Treatments for Steering Joint and Coupling?

Paint Spraying

Painting is the most common surface treatment for steering joints, as it is not limited by color and can be sprayed in various colors.

However, the surface adhesion of spray paint is not strong enough, and it is easy to scratch when encountering knocks. We add a baking process according to this characteristic, which can increase the adhesion of the spray paint surface, and can effectively solve this problem.

Electrophoresis

Electrodeposition is characterized by strong adhesion, a smooth and shiny surface, and not easy to scratch when bumped.

But it can only do black; no other color options.

And because the product needs to be over-acidic during the electrophoresis process, this leads to easy rusting inside the tube.

Neutral Color

Neutral color is not used much in the steering joint; although the product’s surface is coated with anti-rust oil before leaving the factory, the anti-rust time is not long.

Galvanized

The galvanized steering shaft is not used much. The surface is bright and beautiful, and the rust prevention is powerful.

How to See The Steering Joint Quality?

1. Check the appearance

Check the surface treatment for defects, bumps, or rust, then check the finish of the machined surface.

2. Check the burrs

Check the screw holes and keyways for uncleaned burrs, and this detail is something many small factories will overlook.

3. Check the universal joint

Check whether the universal joint oil seal has ruptured; the universal joint is one of the essential parts of the steering joint; if the oil seal ruptures, it will lead to the overflow of lubricating grease inside the bearing cup and the dirt and dust outside into the universal joint, which will lead to the life of the universal joint is significantly shortened.

4. Turning universal joint

Check whether the rotation is smooth; if there is a jam, the steering joint will have a strange sound in the process of use; feel whether there is a gap in the universal joint during the rotation Universal joint if there is a gap, the steering wheel will have a gap after the product is installed, which will affect the precision of the steering wheel rotation, resulting in increased driving danger.

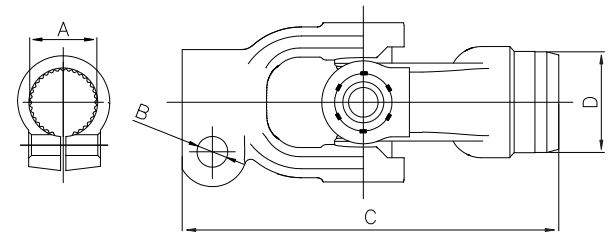

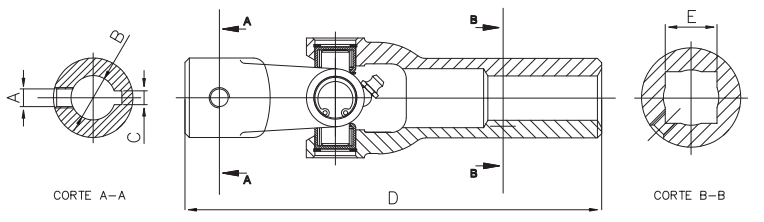

5. Check the length

Measure the correct length of the product.

6. Check the dimensions

Measure the mounting position dimensions, including the diameter of the inner and outer spline, the number of teeth, the spline parameters, and the angle of the mounting position at both ends are correct.

7. Check the thread

Check if the thread specification is correct.

8. Check the spline

Use a thorough gauge to check if the spline parameters are correct.

9. Check other accessories

Check whether other accessories are complete, such as screws, nuts, gaskets, and other accessories.

What are the Most Common Problems that Occur with Steering Joints?

1. The universal joint quality is too poor to cause various problems.

For example, the universal joint clearance is too large, which causes the steering wheel to have a false position and is not sensitive.

The universal joint does not fit smoothly, and there is a snag in the rotation; this can lead to jerky and uneven steering.

Poor quality of the universal joint grease seal, resulting in grease leakage, will significantly reduce the service life of the steering shaft.

2. Spline parameter error.

For steering joints, spline parameters are critical. The product will not be installed and used if the spline is wrong.

What is our Solution?

For these problems, we offer the perfect solution.

1. We use the world’s best brand “Wanxiang” for universal joints, the best supplier globally.

The gap in the universal joint, jamming, and grease seal leakage can be avoided entirely.

2. To address the problem that spline parameters are prone to errors, we have made unique spline through gauges for each spline specification and bore. Make sure every spline is thoroughly inspected to avoid any wrong product in your hand.

Production Process of The Commercial Truck Steering Joint

Here is the production process of commercial truck steering joints to let you know how they are made.

- 1 . Make a drawing.

Draw the drawing according to the OE sample.

- 2. Make the mold.

Make the mold of the yokes.

- 3. Produce roughs.

Forging or casting the roughs.

- 4. Make the machining.

Machining of these steel parts, turning, drilling and milling.

- 5. Make the spline.

Machining splines.

- 6. Assemble.

Assemble all parts; we buy u joint from “Wanxiang,” the No. 1 brand in the world.

- 7. Make the surface treatment.

Different surface treatments for products according to other products and customer requirements. Painting, electrophoresis, phosphating, galvanizing, zinc-nickel alloy, natural color, etc.

- 8. Laser mark.

Laser mark your logo on the steering joint and coupling surface.

- 9. Packaging.

Bagging and packing them.

Inspection Process of Commercial Truck Steering Joint

- 1. Roughs inspection.

Every rough will be inspected before machining to avoid any defective and missing roughs in the following process.

- 2. Machined parts inspection.

Each machined part will be fully inspected, first by the supervisor of the first inspection, then by the production line workers each full inspection; the inspector will also regularly perform random checks; once found that there is a dimensional failure of the product, it must be immediately dealt with.

- 3. After surface treatment inspection.

Every part that has been surface treated must be thoroughly inspected, and any defective ones cannot flow into the following process.

- 4. Assembled parts inspection.

The workers will self-inspect each product during the assembly process, and the inspectors will also conduct random inspections at regular intervals. Mainly check whether there is clearance in the universal joint and whether there is clearance in the spline shaft and shaft tube fit.

- 5. Finished product inspection.

All finished products will be inspected individually, including checking the appearance and measuring the size, angle, and clearance.

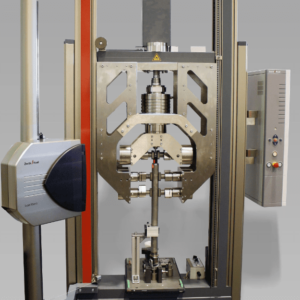

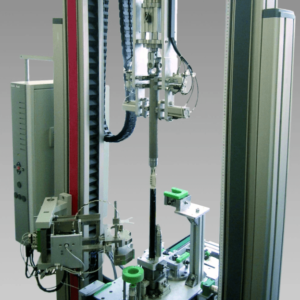

- 6. Performance Testing.

A few randomly selected finished products to do performance testing. Mainly do static torsion test; the test results must reach 300NM or more. Next, do the gap fit test; the test result needs the gap to be less than 0.03mm. Finally, do the fatigue test 1 million times; the test result requires the product to be intact.

- 7. Package inspection.

Packaging is also a full inspection of each product, mainly to see whether the laser typing on the product, bags, boxes, labels, and markings meet customer requirements.

Steering Joint Package

We offer two packaging models. The first is your branded packaging, and the second is neutral packaging. Whatever your packaging requirements, please let us know, and we’ll take care of it for you!

Brand Packing

- 1. Laser marking your logo on product.

- 2. Put the product in your branded colorful bag.

- 3. Put the bag into your branded colorful box.

- 4. Stick your brand label onto your box.

- 5. Put the boxes into your branded colorful carton.

- 6. Stick your shipping mark onto cartons.

- 7. Make the cartons to pallet or wooden box.

Neutral Packing

- 1. Put the product into white bag.

- 2. Put the bag into neutral brown box.

- 3. Stick neutral label onto box.

- 4. Put the boxes into neutral brown carton.

- 5. Stick your shipping mark onto cartons.

- 6. Make the cartons to pallet or wooden box.

Commercial Trucks steering joints listing...

| / | JU-801 |

| / | JU-802 |

| / | JU-803 |

| TAR415721A TAR415-725 | JU-807 |

| 344.268.7089 1760.431.025.3 | JU-813/ JU-929 |

| 000.268.1489 344.268.7189 345.268.7089 | JU-814 |

| 344.260.8033 352.260.2133 | JU-815 |

| 7.111.446 316.460.0057 344.460.7057 6.884.459 | JU-816 |

| 250.296 | JU-817 |

| 223.895 233.895 | JU-818 |

| / | JU-820 |

| / | JU-821 |

| 364.268.7289 | JU-823 |

| 3761698001A | JU-824 |

| / | JU-825 |

| HJU-828 | |

| 688.462.7044 | JU-840 |

| 364.268.0289 | JU-850 |

| 7.111.446 316.460.0057 344.460.7057 6.884.459 | JU-866 |

| JU-869 | |

| 8.133.000 3.038.133 | JU-870 |

| 1.606.502 8189503 1326778 1001490 | JU-884 |

| 0366126 0367847 1989601 | |

| 1613607 8189504 | |

| 327.460.0157 352.460.0057 | JU-887 |

| 2680900526 | JU-888 |

| 000.460.0157 3444607057 | JU-946 |

| 000.460.0057 | / |

| / | JU-972 |

| / | JU-977 |

| / | JU-833 |

| / | JU-842 |

| / | JU-973 |

| / | JU-975 |

| / | JU-978 |

| / | JU-956 |

| T00 415 721A | JU-861 |

| 2R0 415 065 A/ T00 415 721 | |

| JU-000 | |

| 3142601114 | |

| JU-983 | |

| JU-980 | |

| JU-981 | |

| JU-982 | |

| JU-983 | |

| 1768957 3100487 | / |

| 1768962 | / |

| 1386424 1356022 550268 | / |

| 000.268.4601 |

What People are Saying About Us?

FAQ about Our Commercial Truck Steering Joint

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

- Check whether the product pictures are consistent.

- Also, verify that the product OE or standard primary manufacturer number is correct.

- Then, check if the applicable model and year are accurate.

- Finally, check if the product length and mounting dimensions are correct.

- Accurate factory price, no intermediary.

- We have our forging plant, and we make all forging roughs ourselves, which means we have a more significant cost advantage than others.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity for the steering joint is 100 pcs, and for the steering shaft, the minimum order quantity is 50 pcs.

Yes, we offer free samples for your test.

All products from 1A Steering Shaft are covered with a 12 Months warranty from the date of installation or 18 Months warranty from the shipment date, whichever comes earlier.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Usually, for old products, the lead time will be less than 45 days; for newly developed products, the lead time will be 60 days.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, the brand colorful package service is our leading service; it contains laser marking your logo on the product surface or roughs, printing your brand colorful bag, printing your brand labels, make your brand colorful box and cartons.

Our brand-colorful package service is the perfect way to ensure your product stands out in the market. We offer a wide range of customizations that can help you get the most out of your product. Our team specializes in laser marking, which allows us to place your logo or design onto the surface of any product with precision and accuracy.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

Who paid for the mold, and who owns the mold.

Send Us Your Inquiry Now!

Please fill out the form on the right to send us an inquiry. We always want to ensure that our customers get the best deal, so let us know what you’re interested in, and we’ll get back with a quote!