Cars, Trucks, and Agricultural Machinry Front & Rear Axle Shaft Manufacturer & Supplier Since 2008

Trusted Front Axle Shaft Factory

"JIUREN AUTO PARTNER" Company Overview

Yuhuan Jiuren Machinery Co., Ltd was founded in 2008 and is a professional manufacturer of steering shafts, drive shafts, and axle shafts. Specialized solutions for cars, trucks, agricultural machinery, and UTVs.

We provide OEM, ODM, and custom services; our products are mainly exported to the USA, Canada, Mexico, Brazil, Argentina, Peru, Australia, New Zealand, Germany, France, the UK, Italy, Netherlands, Poland, Russia, Ukraine, Spain, Hungary, Turkey, Saudi Arabia, Malaysia, Thailand, etc.

In the automotive field, our producta are mainly for Toyota, Honda, Nissan, Mitsubishi, Lexus, Suzuki, Isuzu, Mazda, Daihatsu, Subaru, Infiniti, Mercedes-Benz, BMW, Audi, Volkswagen, Volvo, Porsche, Jeep, Ford, Lincoln, Dodge, Chevrolet, Buick, Cadillac, Chrysler, Hummer, GM, Kia, Hyundai, Land Rover, Jaguar, Renault, Fiat, Peugeot, Opel, Lada, UAZ.

In the truck field, our products are mainly for Mercedes-Benz, Scania, Volvo, Iveco, DAF, Volkswagen, Ford, dump trucks, Basculantes, etc.

In the agricultural machinery field, our products are mainly for John Deere, Case IH, Kubota, New Holland, etc. In the UTV field, our products are mainly for Polaris and Can-Am. Etc.

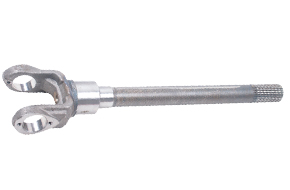

Featured Axle Shaft in The Market

| 33027-2304064-01 |

| 23107-2304066 |

| 33027-2304065-01 |

| 23107-2304067 |

| 33027-2304063-01 |

| 23107-2304063 |

| 22177-2304077 |

| 33027-2304061 |

| 33027-2304060 |

| 23107-2304061 |

| 23107-2304060 |

| 22177-2304061 |

| 22177-2304060 |

| 1332622 1380208 | Polaris 3-2010 600 700 EFI Sportsman 800 200 |

| 1380110 | Polaris ATV 1999 SPORTSMAN 335 – Polaris ATV 1999 DIESEL Polaris ATV 1998 SPORTSMAN 500 Polaris ATV 1998 SWEDISH SPORTSMAN 500 Polaris ATV 1997 SPORTSMAN 500 Polaris ATV 1997 SWEDISH SPORTSMAN 50 |

| F81Z 3220-BA |

| F81Z 3219-BA |

| 10013781 |

| 10013778 |

| 5015137AB |

| 5015136AB |

| 4874303 |

| 4874302 |

| 5083667AA |

| 5083666AA |

| 68004081AA |

| 68004080AA |

| 68145209AA |

| 68145208AA |

| 68019326AA |

| 68413468AA |

| 68400739AA |

| 68397156AA |

| 68400738AA |

| 68397157AA |

| 68055221AA |

| 5086666AB |

| 5086667AB |

| 5010874AA |

| 2013563-1 |

| 2014169-2 |

| 2014616-1 |

| 2014616-2 |

| 2022236-2 |

| 68034434AC |

| 68034435AC |

| 68055220AA |

| 68055221AA |

| 68065426AB |

| 68065427AB |

| 68213880AB |

| 68213888AB |

| 68213889AB |

| 68216196AA |

| 68216197AA |

| 68456986AA |

| 68456997AA |

| 708063 |

| 74760-1X |

| 75265X |

| 75815-2X |

| 76472X |

| 76627X |

| 40179031K |

| 40179035K |

| 10014980 |

| 10015196 |

| 10044423 |

| 10044425 |

| 2001874 |

| 27902-1X |

| 27902-25X |

| 36617 |

| 40955 |

| 46003022 |

| 46901 |

| 49490 |

| 660182-6 |

| 68034433AA |

| 68216998AA |

| 68397155AA |

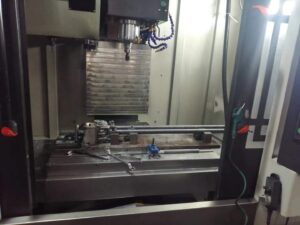

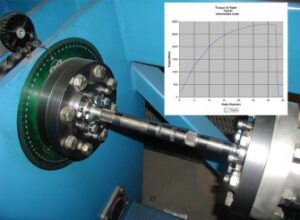

Production Photos of GAZ/JEEP Front Axle Shaft

What are the Technical Standards for Axle Shaft?

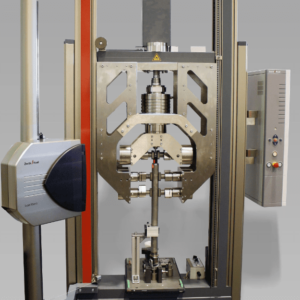

- 1 . Torque test

The axle shaft is to play the function of transmitting power to the tires, so it requires a high level of torque. The national standard of static torque of the axle shaft is to reach 3000 Nm, our axle shaft static torque can reach 4000 Nm.

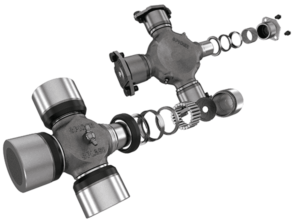

- 2 . Universal joint clearance

The universal joint is an important component of the axle shaft, so the clearance of the universal joint is also an important performance that affects driving. The national standard of universal joint clearance is 0.03-0.05mm, and our universal joint clearance is generally lower than 0.03mm.

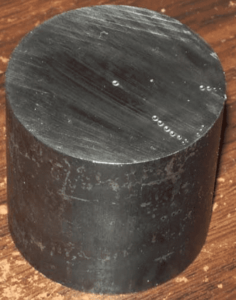

- 3 . Shaft hardness

The hardness requirement of the axle shaft is also a critical performance indicator. The national standard of axle shaft hardness is 48-56 HRC. Our axle shaft hardness can reach 50-56 HRC.

- 4 . Heat treatment depth

The depth of heat treatment directly affects the hardness, torque and strength of the axle shaft, so this is also an important performance indicator. The national standard of heat treatment depth is 3.5-5mm, our products can reach 3.5-5mm.

Inspection Process of Commercial Truck Steering Shaft Column

- 1. Roughs inspection.

Every rough will be inspected before machining to avoid any defective and missing roughs in the following process.

- 2. Machined parts inspection.

Each machined part will be fully inspected, first by the supervisor of the first inspection, then by the production line workers each full inspection; the inspector will also regularly perform random checks; once found that there is a dimensional failure of the product, it must be immediately dealt with.

- 3. Nylon coating inspection.

Check whether the nylon coating is uniform and if there is no breakage in the place.

- 4. After surface treatment inspection.

Every part that has been surface treated must be thoroughly inspected, and any defective ones cannot flow into the following process.

- 5. Assembled parts inspection.

The workers will self-inspect each product during the assembly process, and the inspectors will also conduct random inspections at regular intervals. Mainly check whether there is clearance in the universal joint and whether there is clearance in the spline shaft and shaft tube fit.

- 6. Finished product inspection.

All finished products will be inspected individually, including checking the appearance and measuring the size, angle, and clearance.

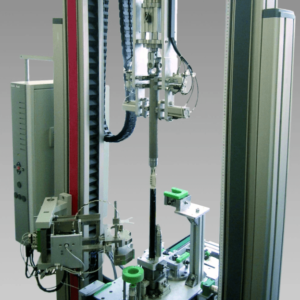

- 7. Performance Testing.

A few randomly selected finished products to do performance testing. Mainly do static torsion test; the test results must reach 300NM or more. Next, do the gap fit test; the test result needs the gap to be less than 0.03mm. Finally, do the fatigue test 1 million times; the test result requires the product to be intact.

- 8. Package inspection.

Packaging is also a full inspection of each product, mainly to see whether the laser typing on the product, bags, boxes, labels, and markings meet customer requirements.

- Real factory price, no middleman.

- Two years of warranty, quality is comparable to the original.

- Lowest 100 pcs MOQ request.

- Fastest 45 days delivery.

What People are Saying About Us?

FAQ about Our Commercial Truck Steering Shaft Column

These are the most frequently asked questions. If you cannot find an answer here, please get in touch with us via email.

- Check whether the product pictures are consistent.

- Also, verify that the product OE or standard primary manufacturer number is correct.

- Then, check if the applicable model and year are accurate.

- Finally, check if the product length and mounting dimensions are correct.

- Accurate factory price, no intermediary.

- We have our forging plant, and we make all forging roughs ourselves, which means we have a more significant cost advantage than others.

We are a family business manufacturing located in Yuhuan city, China’s largest automotive chassis parts zone. There are tens of thousands of factories of automotive chassis parts here. So you can find any chassis parts here.

Usually, the minimum order quantity for the steering joint is 100 pcs, and for the steering shaft, the minimum order quantity is 50 pcs.

Yes, we offer free samples for your test.

All products from 1A Steering Shaft are covered with a 12 Months warranty from the date of installation or 18 Months warranty from the shipment date, whichever comes earlier.

We offer EXW, FOB, CFR, CIF, and Door to Door delivery terms.

- Pay 30% in advance and 70% before shipment by T.T.

- 100% payment before shipment by T.T.

- 100% payment aginst BL copy by T.T.

- 100% payment 30 days from shipping date by T.T.

All shipment products are documented, and we provide OEM services to many brands without any information about our manufacturer of the goods. Any drawings, operating instructions, test reports, etc., belong to the brand owner.

Usually, for old products, the lead time will be less than 45 days; for newly developed products, the lead time will be 60 days.

Yes, custom service is our leading service, tell us your requirements, and we’ll take care of the rest.

Yes, the brand colorful package service is our leading service; it contains laser marking your logo on the product surface or roughs, printing your brand colorful bag, printing your brand labels, make your brand colorful box and cartons.

Our brand-colorful package service is the perfect way to ensure your product stands out in the market. We offer a wide range of customizations that can help you get the most out of your product. Our team specializes in laser marking, which allows us to place your logo or design onto the surface of any product with precision and accuracy.

- Provide samples, and we will make drawings, or you can provide us with detailed production drawings.

- Then, make a mold and produce a few roughs.

- Produce pre-production samples and send them to you for confirmation.

- After your side approves the samples, we will start mass production.

- If you do not confirm the sample, we will make changes according to your requirements and resend the sample to you until you approve the sample.

- After the mass production, you can arrange for a third party to inspect the goods, or we will send you samples of large goods for your inspection.

- After you approve, we will ship your goods.

Who paid for the mold, and who owns the mold.

Send Us Your Inquiry Now!

Please fill out the form on the right to send us an inquiry. We always want to ensure that our customers get the best deal, so let us know what you’re interested in, and we’ll get back with a quote!